How many days can the formwork be removed during construction? The following analysis will help you better understand the hardening of the concrete and the time it takes to remove the formwork.

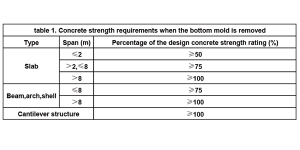

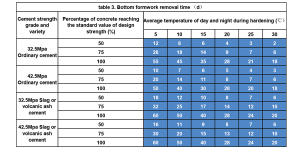

Load-bearing formwork: For detailed time requirements, see Section 4.3.1 of the “Code for the Acceptance of Construction Quality of Concrete Structures”. The percentage of the standard value of the compressive strength of the design concrete cube that needs to be achieved for different components.

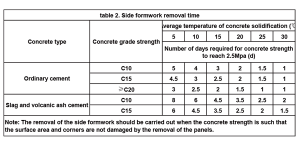

Non-load-bearing formwork: side formwork including foundation, column and press top, and side formwork of beam and wall. When it is removed, the strength and surface can be removed without being damaged due to demoulding. However, for large wall formwork, it can be removed when the strength reaches 1N/mm² at room temperature.

General requirements for formwork removal

(1) The strength of the concrete during demoulding shall comply with the design requirements; when the design is not required, the following provisions shall be complied with:

- Non-load-bearing side formwork, including side slabs of beams, columns and walls, as long as the concrete can ensure that its surface and edges are not damaged by the removal of the formwork, it can be removed.

- Load-bearing formwork, including the bottom mold of horizontal structural members such as beams and plates, shall be removed according to the strength of the test block maintained under the same conditions as the structure.

- In the process of demoulding, if it is found that the actual concrete strength does not meet the requirements and there are quality problems affecting the structural safety, the demoulding should be suspended. After proper treatment, the actual strength can meet the requirements before proceeding.

- When the concrete structure of the formwork and its support has been removed, the concrete load should be accepted until the concrete strength reaches the designed concrete strength standard value. If the effect of bearing the construction load is more unfavorable than the use of the load, it must be accounted for and added temporary support.

- The inner mold or the reserved hole shall be removed only when the strength of the concrete can be ensured without collapse and crack.

(2) Before demolishing the plastic formwork, there must be an application for demoulding. When the technical record of the maintenance test block at the same condition reach the target rule, the technical PIC can approve the demoulding.

(3) The formwork and support system of the post-casting area shall not be dismantled without the approval of the technical PIC (the area after the reserved pouring zone shall not be removed).

(4) The formwork of the hanging material hole and the cantilever end and the supporting system are not allowed to be removed when the cross is forbidden.

(5) For large-volume concrete, in addition to meeting the concrete strength requirements, insulation measures should also be considered. After demoulding, it is necessary to ensure that the temperature difference between the inside and outside of the concrete does not exceed 200℃, so as to avoid temperature difference cracks.

(6) When the formwork is removed, the strength of the concrete must meet certain requirements. If the concrete does not reach the specified strength and must be demolished in advance, it must be calculated before it can be removed. (reserve more concrete test blocks, the concrete test blocks before demoulding are tested)

(7) The order and method of demoulding shall be carried out in accordance with the provisions of the plastic formwork support design book, or the first formwork shall be dismantled later, the post formwork shall be dismantled firstly, the non-bearing formwork shall be dismantled firstly, the load-bearing formwork shall be dismantled later. The principle of top-down should be strictly followed.

(8) The removed formwork must be cleaned up with the dismantling, and the removed plastic formwork panels must be piled up to prevent the damage by steel pipe.

(9) There should be no people below when demolishing the mold, and a warning line should be set in the demoulding area to prevent someone from being mistaken for being bruised.

(10) The removed formwork panel is transported downwards with careful, it is necessary to take one by one to avoid a large piece of slump during the removal. When lifting the demolished formwork panels with a crane, the formwork should be piled up neatly and tied up before it can be lifted, otherwise it will cause splash in the air.

- Cast-in-place floor and frame structure demoulding

(1) Form of demolition of cast-in-situ slab or frame structure: detachment of column mold and column hoop → split side mold → split floor slab → detachment beam side mold → beam bottom support system → beam bottom mold.

(2) When removing the formwork, stand in a safe place.

(3) When removing the formwork, it is strictly forbidden to use a crowbar or a hammer to smash. For the large piece of panel to be removed, it should be properly stabilized and placed on the ground. It is strictly forbidden to throw.

(4) Remove the bracket, the wood should be nailed in time, piled up neatly according to the specifications. When the project is completed (formwork project), the formwork panels should be dropped by the hanging orchid (the mold material is forbidden to be thrown from a high place), and piled up at the designated place, then transported to the company warehouse for storage.

(5) When removing the lower strut of the beam with a large span, it should be removed from the middle of the span and removed to the ends.

(6) The moving parts must be dismantled once, and stopped after the disassembly. If the dismental work is break, the moving parts must be fixed firmly to avoid accidents.

(7) For horizontal pull-up, first remove the pull-up support, and finally remove the horizontal pull-up.

(8) There are multiple horizontal tie rods on the formwork column. The upper part should be removed first and removed in the order from top to bottom. The last link should be removed at the same time as the column is removed to prevent the column from tipping and injuring people. -

Demolition of cast-in-place column formwork

(1) The removal shall be from top to bottom, and the formwork and support shall not be thrown to the ground.

(2) The formwork should be gently moved, hammering is strictly prohibited, and should be stacked with the designated location.

(3) The order of column formwork removal is as follows: remove the diagonal bracing or tie rod (or steel bracing) → remove the column hoop or crossbar from top to bottom → remove the mullion and remove the formwork joint and formwork panels from top to bottom.

- The removed formwork is strictly prohibited from being stacked on the scaffolding.