2 Effective measures to solve the main problems in the construction process of building formwork

2.1 Strengthening technical management before construction

The construction of the formwork structure involves various construction links, therefore, it is not only necessary to use the formwork design drawing as the standard, but also to combine the overall construction process design drawings to ensure that the formwork configuration is in line with the overall construction requirements. At the same time, it is necessary to check the specification model, size and shape of the template to ensure the scientific and rational internal structure, which is also a key point to ensure the stability and reliability of the building.

In the case of conditions, the precision calculation instrument should be used to measure the bearing load force, the weight and the pressure it brings, and simulate the effect of the formwork structure to ensure the scientific design. And reasonableness. Avoid temporary changes to the formwork construction process due to imperfections in the design, resulting in a large amount of labor cost loss and cost waste.

2.2 Reasonable selection of construction technology

The correct selection of the construction technology of the building formwork is very important. It is necessary to select the appropriate process that meets the construction requirements according to the different conditions of the project and the actual conditions of the construction site to achieve the best use effect.

First of all, the construction drawings are required as the main basis for the process selection. According to the requirements of the template structure in the drawings, such as the size, the shape and the connection between the materials, it is guaranteed that it can be carried out according to the construction sequence, avoiding the occurrence of leakage and causing the instability of the template structure;

Secondly, since the formwork needs to be dismantled later, it is necessary to select a construction process that is easy to install and disassemble, paving the way for the subsequent unfolding of the formwork removal work, but at the same time ensuring that the construction process meets the construction requirements;

Third, since the application of concrete structures or steel structures in buildings is relatively common, it is necessary to consider the structural weight and the pressure on the formwork to ensure that it is smaller than the bearing capacity of the formwork. This process requires precise calculations and detailed analysis to ensure that the formwork can carry the overall structural pressure of the building, thus effectively improving the overall stability of the building;

The fourth is to develop a solution to the problems that may arise from the formwork connection point. Usually, the formwork connection point bears the pressure of the connection between the various plates, and the pressure load on the contact is the largest, so it is also the most problematic item. In view of this situation, the joints of the formwork panels should be treated, and the gaps of the joints should be ensured in a scientific way by filling and welding to meet the technical requirements of the construction of the building formwork.

To be continue…

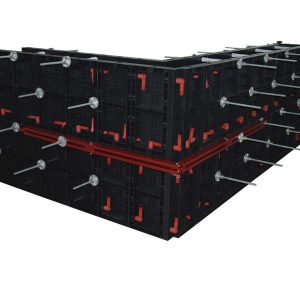

BOFU plastic formwork system